Conceptual Shift: Molecules to Electrons

- Global industry is transitioning from fuel-based molecules to electricity-driven electrons for competitiveness.

- Electrification enables automation, process control, and easier decarbonisation across manufacturing systems.

- Electric motors convert over 90% input energy into work, far exceeding internal combustion efficiency.

Comparative Global Position

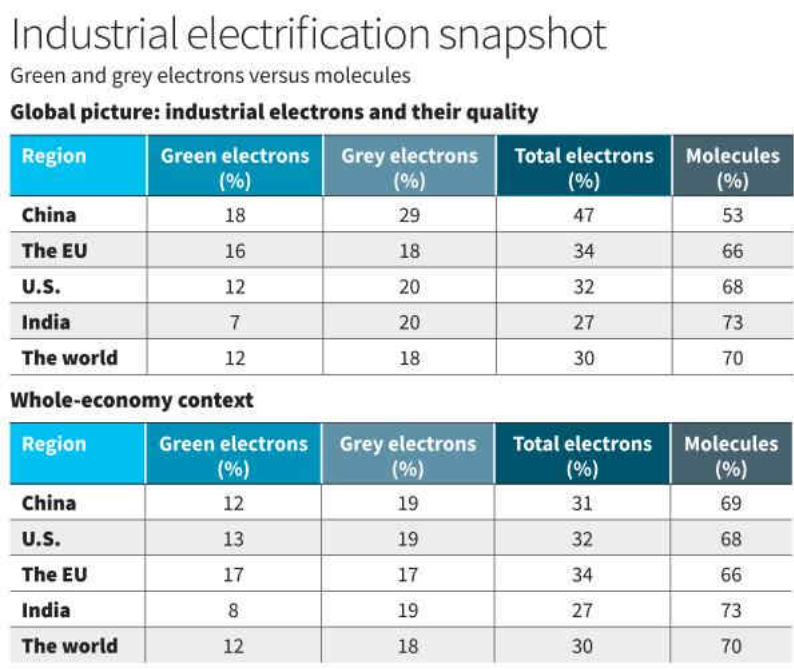

- In 2024, nearly half of China’s industrial energy came from electricity.

- India’s share remains near one-quarter, affecting export competitiveness and energy security.

- China leads in both quantity and quality of green electrons across industrial sectors.

- Economy-wide electrification: China 31%, United States 32%, European Union 34%.

China’s Industrial Electrification Strategy

- Massive investments in generation, ultra-high-voltage transmission, grid storage, and substations since 2010.

- Electric-arc-furnace steel output increased from 44 million tonnes in 2010 to 106 million tonnes in 2024.

- Waste-heat recovery in cement contributes 30–35 kWh per tonne, improving energy efficiency.

- Policy supports scrap recycling and preferential tariffs to expand electric steel production.

India’s Starting Conditions and Gaps

- India doubled grid capacity in a decade and leads global solar additions.

- Green electrons constitute only 7–8% of final energy use in industry.

- Key barriers include legacy on-site combustion, uneven power reliability, and limited process electrification policies.

Sectoral Roadmap for India

- Steel sector: Around 30% production uses electric-arc furnaces, compared to 70% in the U.S.

- Improved scrap collection, renewable-linked EAF incentives, and CBAM readiness are necessary.

- Cement sector: Support electrified kilns, waste-heat recovery, and CCUS pilot hubs.

- MSMEs: Promote electric boilers, induction furnaces, and pooled renewable power procurement.

Strategic Importance Beyond Climate

- Export competitiveness improves as buyers demand low-carbon manufacturing supply chains.

- Energy security strengthens by reducing dependence on imported oil and gas.

- Industrial sovereignty increases through location decisions based on skills, not fuel availability.

Policy Direction

- Focus on megawatt-hours flowing into factories, not only renewable generation capacity.

- Propose a national mission on industrial electrification and targeted MSME finance support.